Why Safety Edges Are Essential for Tire Vulcanizing Machine Operations

- Share

- publisher

- Zoe

- Issue Time

- Dec 19,2024

Summary

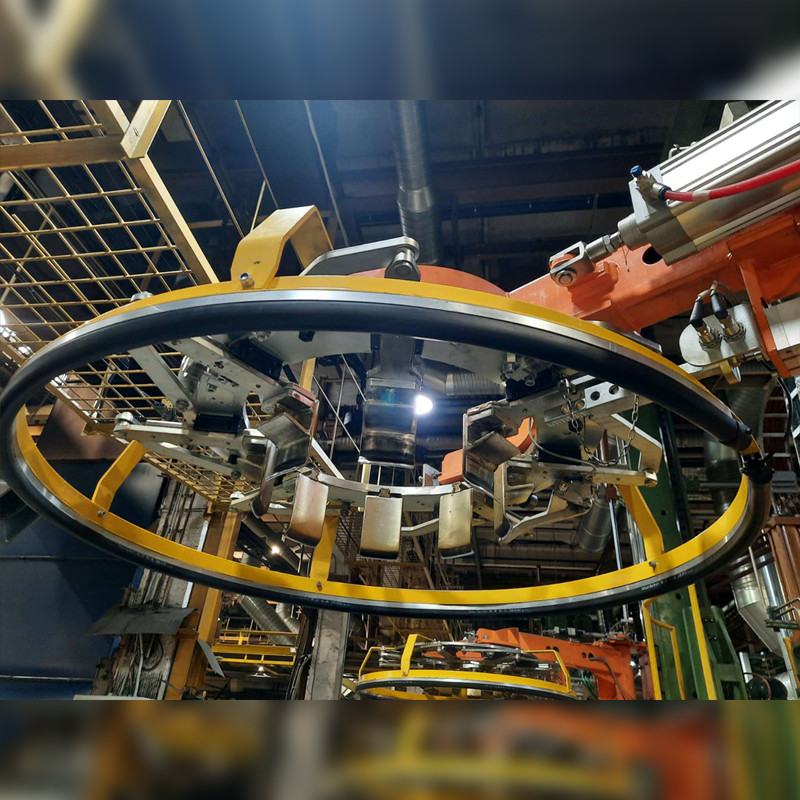

The tire shaping and vulcanizing machine is a critical piece of equipment in the tire manufacturing process. Operating in a high-temperature and high-pressure environment, it requires robust safety measures. Safety edges play an indispensable role in ensuring personnel safety and maintaining equipment stability.

Why Safety Edges Are Essential for Tire Vulcanizing Machine Operations

The tire shaping and vulcanizing machine is a critical piece of equipment in the tire manufacturing process. Operating in a high-temperature and high-pressure environment, it requires robust safety measures. Safety edges play an indispensable role in ensuring personnel safety and maintaining equipment stability.

Challenges in Tire Vulcanizing Machine Safety

1. Risk of Injury to Personnel

During the mold-closing process of the vulcanizing machine, the upper and lower molds may cause serious injuries if an operator’s hands or other body parts come into contact with the mold edges. The safety edge detects such contact immediately and sends a signal to stop the mold-closing action, effectively preventing accidents.

2. Risk of Equipment and Tool Damage

Tools or parts used for maintenance and inspection are sometimes left near the machine's operating area. If these objects are caught between the closing molds, it could lead to damage to the molds or other equipment components, potentially disrupting production. The real-time detection capability of the safety edge prevents such incidents.

How Safety Edges Solve Them

1. Definition and Working Principle of Safety Edge

A safety edge is a protective device installed along the edges of machinery. Typically made of elastic materials such as rubber or plastic, it contains conductive cores inside. When the safety edge is subjected to pressure or compression, the conductive cores inside make contact, altering the circuit state. This triggers an immediate stop or alarm function.

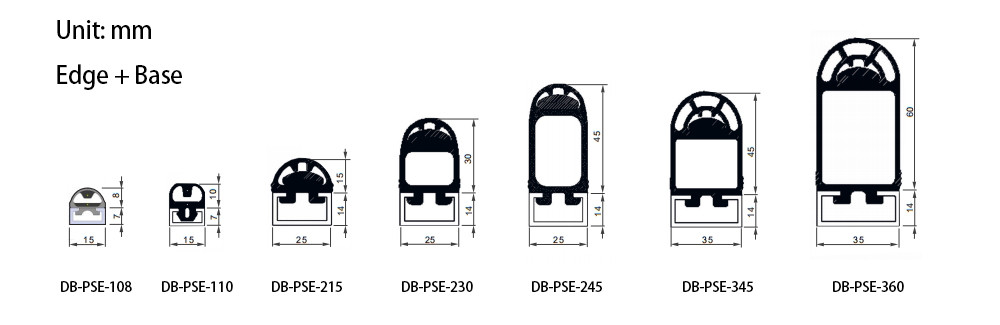

DB-PSE Series Safety Edges Models

▪️ Detection Method: Pressure sensing

▪️ Maximum Detection Angle: Less than 90°

▪️ Trigger Force (depending on specifications and usage): ≥ 25 N - 250 N

▪️ Mechanical Lifespan: > 3,000,000 cycles

▪️ Surface Protection Material: EPDM rubber, CR rubber

▪️ Operating Temperature: -20°C to 55°C

▪️ Protection Rating: IP65

▪️ Maximum Humidity (at 23°C): 95% (no condensation)

Response Time: 13 ms

|

Models

|

Base width

|

Actuation distance |

Actuation force

|

Overtravel distance

|

Applications (R: Radius of Curvature) | |

|

DB-PSE-108

|

15 mm

|

< 2 mm |

≤ 25 N

|

0

|

Small AGV, R ≥ 50 mm | |

|

DB-PSE-110

|

15 mm

|

< 2 mm |

≤ 25 N

|

0

|

Small AGV, garage access control, industrial applications, etc, R ≥ 150 mm | |

|

DB-PSE-215

|

25 mm

|

< 3 mm |

≤ 25 N

|

0

|

AGV, electric door, industrial applications | R ≥ 300 mm |

DB-PSE-230 | 25 mm | < 3 mm | ≤ 25 N | < 19 mm | R ≥ 450 mm | |

DB-PSE-245 | 25 mm | < 3 mm | ≤ 25 N | < 30 mm | R ≥ 450 mm | |

DB-PSE-345 | 35 mm | < 5 mm | ≤ 100 N | < 30 mm | Large AGV anti-collision, heavy-duty industrial doors, machinery, and industrial applications, R ≥ 600 mm | |

DB-PSE-360 | 35 mm | < 5 mm | ≤ 100 N | < 45 mm | ||

Downloads

2. Key Functions of the Safety Edge

▪️ Hazard Zone Detection

Safety edges are installed around moving parts of the vulcanizing machine (such as molds or robotic arms) to monitor whether a person or object is approaching the hazardous area in real time.

▪️ Emergency Stop Protection

When an operator or foreign object touches the safety edge, the system immediately sends a stop signal to halt machine operations, preventing injury or damage.

▪️ Equipment Protection

Safety edges can detect tools or parts unintentionally left near the mold area, stopping the machine’s actions and preventing mold or equipment damage.

3. Recommendations for Comprehensive Application

In tire manufacturing plants, it is recommended to integrate safety edges with other safety devices such as light curtains and emergency stop buttons to establish a multi-layered safety system. This ensures the safety of operators and enhances the reliability of equipment operations.

View Catalog

Related Safety Products

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety edges are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.